LA NOSTRA TECNOLOGIA PER LA PRODUZIONE

BioSyntex ha sviluppato tre soluzioni tecnologiche proprietarie per la coltivazione di microalghe e cianobatteri:

BSX-ASL

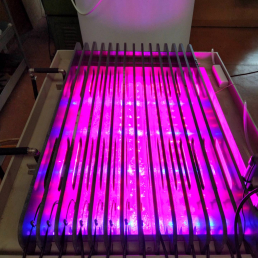

Il fotobioreattore ibrido a colonna anulare BSX-ASL sfrutta la luce solare ed artificiale generata da una cover LED ad alta efficienza. L’unità base è costituita da un Modulo skid Industriale Scalabile (MIS), composto da 32 fotobioreattori (28.000L; footprint <200 m²)

BSX-SLP

Il fotobioreattore a concentrazione solare BSX-SLP sfrutta la radiazione solare e la convoglia, mediante fibre ottiche e tubi diffusori, all’interno dei fotobioreattori. Questo sistema consente di utilizzare la radiazione naturale attraverso un meccanismo di “light dilution”. BSX-SLP è l’ideale per le coltivazioni in siti ad alta radiazione diretta (DNI).

BIO-BOX

Un nuovo reattore compatto disponibile in diversi volumi, il BIO-BOX è equipaggiato con le migliori tecnologie. Un reattore facile da utilizzare e semplice da manutenere in tutti i suoi aspetti.

Le caratteristiche delle nostre tecnologie

- Sono scalabili e modulari

- Lavorano in sinergia con impianti esistenti

- Sfruttano i sottoprodotti industriali (by-products)

- Offrono un elevato livello di automazione

- Gestiscono l’intensità luminosa e gli spettri di luce

- Produzione H24

Grazie al sistema ASL integrato, possiamo coltivare in zone climatiche altrimenti poco favorevoli.

La presenza di una cover LED integrata nella parte superiore del reattore, rende adatto questo sistema sia per le installazioni outdoor che quelle indoor.

Al fine di garantire un’omogenea distribuzione della luce,

abbiamo brevettato un sistema di diffusione della luce che consente di evitare gradienti di intensità luminosa lungo il profilo del reattore.

In base alle specifiche di coltivazione, progettiamo moduli customizzabili secondo le esigenze del cliente, sia per quanto riguarda il volume e le dimensioni dei fotobioreattori, sia per gli spettri di luce.

BSX-SLP

Il fotobioreattore a concentrazione solare BSX-SLP ha la caratteristica di trasferire la radiazione solare, concentrata da pannelli ad inseguimento, per fornire illuminazione diretta (DNI) a colture microalgali o piante nel settore vertical farming.

La concentrazione della radiazione solare diretta avviene con un sistema ottico di focalizzazione (“parquet” di lenti Fresnel) e un Solar Tracker biassiale in accoppiamento con le fibre ottiche.

Un nuovo reattore compatto disponibile in diversi volumi, il BIO-BOX è equipaggiato con le migliori tecnologie. Un reattore facile da utilizzare e semplice da manutenere in tutti i suoi aspetti.

Il BIOBOSCO Urbano ® – powered by BioSyntex S.r.l. – è un’iniziativa smart per le città del futuro che utilizza le proprietà fotosintetiche delle microalghe.

Applicazione sperimentale, intende fornire un antidoto al riscaldamento globale per aree urbane in cui non è possibile, per mancanza di spazio, coniugare la convivenza tra il verde pubblico, le strade, i marciapiedi ed i sottoservizi.

Il BIOBOSCO Urbano ®, con i suoi 10 m2 di occupazione di suolo, assorbe CO2 dall’atmosfera – rilasciando ossigeno nell’ambiente – in una quantità paragonabile ad un boschetto di ca. 25-30 alberi. Le dimensioni e la struttura sono personalizzabili per adattarsi ai diversi contesti urbani.

Il CEO, Dr. Giovanni Gnudi, racconta:

“Si tratta di un’applicazione sperimentale che intende fornire un antidoto al riscaldamento globale per quelle aree urbane in cui non è possibile, per mancanza di spazio, coniugare la convivenza tra il verde pubblico, le strade, i marciapiedi e i sottoservizi.

Il BIOBOSCO Urbano® è una tecnologia pensata per essere complementare e di supporto all’implementazione di verde pubblico in quei contesti in cui le infrastrutture urbane presentano un consumo di suolo elevato.

In appena 10 m2 di terreno occupato, infatti, il BBU® assorbe CO2 dall’atmosfera, rilasciando ossigeno nell’ambiente, in una quantità paragonabile ad un boschetto di 25-30 alberi in circa 500 m2 di terreno.

Siamo consci che si tratta di un piccolo contributo all’ambiente naturalmente, ma con le sue dimensioni ridotte e la struttura architettonica personalizzabile siamo in grado di poterla adattare ai vari contesti urbani.

Attualmente l’azienda sta lavorando per portare nuove installazioni, oltre a quella già effettuata per Eni presso l’ex Gazometro di Roma (presente nelle foto), lungo tratti autostradali, stazioni ferroviarie, metropolitane, porti e aeroporti in Italia e all’estero”.

La biomassa prodotta all’interno dell’ex-Gazometro Ostiense di Eni è destinata ad un’azienda che produce terricci fertilizzanti in campo florovivaistico, la Self Garden S.r.l..

Principali collaborazioni: Self Garden S.r.l. (compost di qualità), Consorzio Italiano Compostatori, Arch. Cesare Griffa (designer); C-LED S.r.l. (illuminazione), Scubla S.r.l. (costruttore skid), CodeBaker Srl (interfaccia hardware-software); Eridani3 (costruttore struttura architettonica), Aksolar S.r.l. (pannelli fotovoltaici).

Per informazioni contattare n.bassi@biosyntex.it o info@biosyntex.it