OUR PRODUCTION TECHNOLOGY

The features of our technologies

The features of our technologies

- Scalable and modular

- Work in synergy with existing plants

- Exploit industrial by-products

- They offer a high level of automation

- Manage light intensity and light spectra

- H24 production

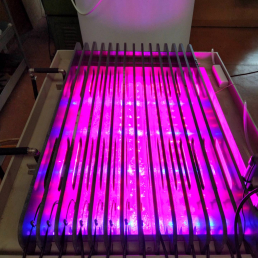

BSX-SLP

BIO-BOX, a new compact reactor available in different volumes, is equipped with the best technology and is easy to use and maintain in every aspect.

The BSX_TGR is equipped with an integrated pig system that facilitates and reduces cleaning time. The glass part is made of Duran® tubes (SCHOTT AG Glass). The BSX_TGR is supplied with a recirculation pump, thermostat system and process control.

The BSX_RWP is an open-pond cultivation system designed for large-scale microalgae production, with an optimized design to enable efficient process management. It features a continuous recirculation system that ensures uniform distribution of nutrients and sunlight, preventing cell sedimentation. It’is constructed with weather-resistant and corrosion-resistant materials to ensure long-term operational durability. All BSX_RWP systems are fully customizable to meet specific client requirements.

BIOBOSCO Urbano ® – powered by BioSyntex S.r.l. – is a smart initiative for the cities of the future using the photosynthetic properties of microalgae.

Dr Giovanni Gnudi, CEO of BioSyntex, shares:

Dr Giovanni Gnudi, CEO of BioSyntex, shares:

“The BIOBOSCO Urbano® is an experimental solution created to address the climate emergency in cities where space is limited and traditional green spaces just aren’t feasible — think roads, pavements and underground utilities all competing for room.

Rather than replace trees, it’s designed to work alongside urban greening strategies, offering support in those high-density areas where land is sealed and built-up.

With just 8 square metres of footprint, each unit can absorb CO₂ and release oxygen at a rate comparable to a grove of 25 to 30 trees spread over 500 m².

It’s a small gesture in environmental terms, yes — but one that’s visible, modular and adaptable, and that can be scaled across the urban landscape where traditional planting is not an option.”

Installed for: IMA S.p.A. and Eni S.p.A.

Circular bioeconomy: Biomass produced is repurposed for composting or agricultural use.

Partners: Stilli Solutions (architecture), Arch. Cesare Griffa (design), C-LED (lighting), Aksolar (solar panels)

For more information: n.bassi@biosyntex.it | info@biosyntex.it